KONECRANES COLLISION AVOIDANCE SYSTEM: SMART TECHNOLOGY FOR SAFER LIFT TRUCK OPERATIONS

Staying alert and maintaining clear visibility around heavy equipment is essential in busy industrial environments where people, vehicles and cargo often operate in close proximity. To help reduce the risk of collisions and improve situational awareness, Konecranes has introduced an advanced Collision Avoidance System designed specifically for its Generation C...

PATERSON SIMONS CONDUCTS KONECRANES LIFTTRUCKS TECHNICAL TRAINING FOR GHANA PORTS & HARBOURS AUTHORITY IN SWEDEN

Paterson Simons has successfully conducted a Konecranes Lift trucks technical training programme for engineers from Ghana Ports & Harbours Authority and our subsidiary Pasico Ghana, in collaboration with Konecranes. The training took place in October 2025 in Markaryd, Sweden, and was delivered in two groups of nine participants each. The...

ELIMINATE BLIND SPOTS WITH THE KONECRANES REVERSE CAMERA KIT

Maintaining a clear view behind a lift truck when reversing is essential for safe, efficient operations. The Konecranes Reverse Camera Kit is designed to eliminate blind spots, giving operators greater confidence when manoeuvring large or heavy loads. Advanced features for safer operations The system provides a wide 120° field of...

WHITEPAPER: ENHANCING PORT SAFETY WHILE MAXIMISING UPTIME

Ports are inherently high-risk environments, with heavy machinery, moving vehicles and deep water present every day. Keeping people safe must always come first, while poor safety can also lead to equipment damage, downtime and significant operational costs. A proactive safety approach starts with preventive maintenance, correct equipment configuration and well-trained...

KONECRANES UNVEILS NEW ELECTRIC REACH STACKER, EXPANDING ITS ECOLIFTING™ PORTFOLIO!

Konecranes has taken a major step forward in its electrification journey with the launch of its new fully electric reach stacker – an innovation designed for the high-intensity, heavy-duty operations that define today’s global material handling industry. Unveiled to an exclusive audience in Shanghai on 19 November, the new model delivers up...

OPERATORS UNANIMOUSLY AGREE: KONECRANES REACH STACKERS EQUIPPED WITH FLOW DRIVE LEAD TO REDUCED OPERATIONAL STRESS!

Paterson Simons conducted training earlier this year at the Tema port of the Ghana Ports & Harbours Authority (GPHA) for thirty GPHA Reach stacker operators. The training focused on Hydromechanical Variable Transmission (HVT) operation on Konecranes SMV 4636 Reach stackers. Utilizing HVT, Flow Drive from Konecranes effectively manages power at...

MAKE YOUR TYRES LAST LONGER WITH KONECRANES TIRE SAVER

Tyre wear, especially on steering wheels, is one of the most significant maintenance costs in lift truck operations. It is also a major source of rubber waste, which has a lasting impact on the environment. Konecranes Tire Saver is a smart, practical solution that helps you get more mileage out...

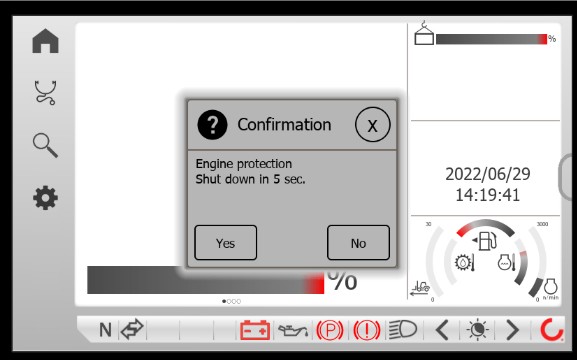

ENGINE SHUTDOWN FUNCTION ON KONECRANES GENERATION C MACHINES CUTS EMISSIONS, LOWERS COSTS, AND PREVENTS DAMAGE

Konecranes engine control function is designed to further extend the lifetime of its Generation C Forklifts and Empty Container Handlers while cutting emissions and operational costs. In addition to the familiar “Start and Stop” function – which automatically powers down the truck when idling or when the operator exits the...

TECHNICAL TRAINING FOR KONECRANES GOTTWALD MOBILE HARBOUR CRANES IN GERMANY

As part of our continued investment in engineering excellence and customer service, Paterson Simons recently completed a two-week intensive technical training programme for Konecranes Gottwald Mobile Harbour Cranes (MHC). The sessions took place at the Konecranes Gottwald Training Centre in Düsseldorf, Germany from 7th to 18th July 2025, with participation from Senior...

EXTEND THE LIFE OF YOUR HYDRAULIC OIL WITH THE KONECRANES HYDRAULIC LONG-LIFE FILTER

With the Konecranes Hydraulic Long-Life Filter, you can safely extend your hydraulic oil’s service life to up to 12,000 operating hours – almost three times longer than conventional filters. That means significantly less oil waste, reduced environmental impact, fewer maintenance stops, and lower operating costs! Wondering when it’s time to...

POWERING PROGRESS: FLEXIBLE PATHWAYS TO ZERO EMISSIONS IN BREAKBULK AND PROJECT CARGO

The road to zero tailpipe emissions looks different for every terminal operator. With Konecranes, you can move toward electrification at a pace that suits your operations, thanks to a wide range of power options across its port equipment portfolio. While electrification is the clear direction for ports globally, breakbulk and...

REDUCE RTG DOWNTIME WITH NEW KONECRANES GEAR REDUCER OVERHAUL KIT!

A new replacement kit from Konecranes is making it easier than ever for port operators to keep their Rubber Tyred Gantry (RTG) cranes running reliably – while reducing the risk of unexpected breakdowns and costly downtime. The Konecranes RTG Gear Reducer Overhaul Kit allows for all critical bearings and seals...