Smooth boom operation is not just part of maintenance – it is fundamental to safe, efficient lifting. Proper lubrication keeps your crane performing at its best, safeguards on-site stability, and protects the long-term value of your equipment.

Following manufacturer lubrication guidelines is essential. Each crane model has a defined greasing schedule, and using the correct formulation plays a critical role. Substituting recommended semi-synthetic grease with mineral or fully synthetic alternatives can reduce lubrication intervals, increase wear, and potentially affect operational performance.

Introducing Boom Grease Plus

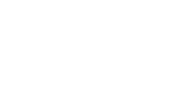

To simplify and optimise boom lubrication, Manitowoc has developed Boom Grease Plus – a purpose-built solution designed to make maintenance faster, cleaner and more effective.

Available as a complete kit or as individual components, Boom Grease Plus integrates seamlessly into preventive maintenance programmes, providing technicians with practical, easy-to-use tools tailored specifically for crane boom care.

Key Benefits

- Ensures smooth, controlled boom movement

- Supports long-term structural integrity

- Reduces the risk of downtime linked to lubrication issues

- Streamlines maintenance with dedicated, job-specific tools

Preventive maintenance remains one of the most effective ways to extend crane lifespan and maintain reliable performance. With Boom Grease Plus, operators and service teams have the right tools to maintain consistent lubrication standards — every time.

Ready to optimise your crane maintenance?!

Get in touch with our parts team via our online contact form here

See the team in action here: